Comprehensive drum test bench program instructions (2)

- 2020-05-11-

2. Suitable vehicles for testing

Axle weight: less than 2000kg

Wheelbase: 1450-1900mm (customizable)

Wheelbase: 2300-3100mm (customizable)

Tire Specification: 15-20Inch

Minimum ground clearance: 100mm

Workstation cycle is less than 3 minutes

3. Detection range and accuracy

Test items | Measuring range, accuracy |

speed | 0-120km\/h; 0.1% full scale |

Static braking force | Greater than 3500N; 1% full scale |

Dynamic braking force | Greater than 3500N; 1% full scale |

Wheelbase adjustment speed and accuracy | Greater than or equal to 60mm\/s, error ±1.0mm |

Front and rear axle speed deviation | Average speed: <0.1km\> Speed change: <0.5km\> |

Related News

- How does the dynamic four wheel aligner avoid communication interference?

- Introduction to vehicle electrical inspection

- How to choose a good pass four wheel aligner

- What is the assembly line

- The important role of the through four wheel aligner

- The four main points of 3D laser four wheel aligner maintenance

- Working principle of electric chassis dynamometer

- Vehicle off-line comprehensive diagnostic equipment

- How to choose a good dynamic four wheel aligner

- Precautions for selecting a non-contact four-wheel aligner

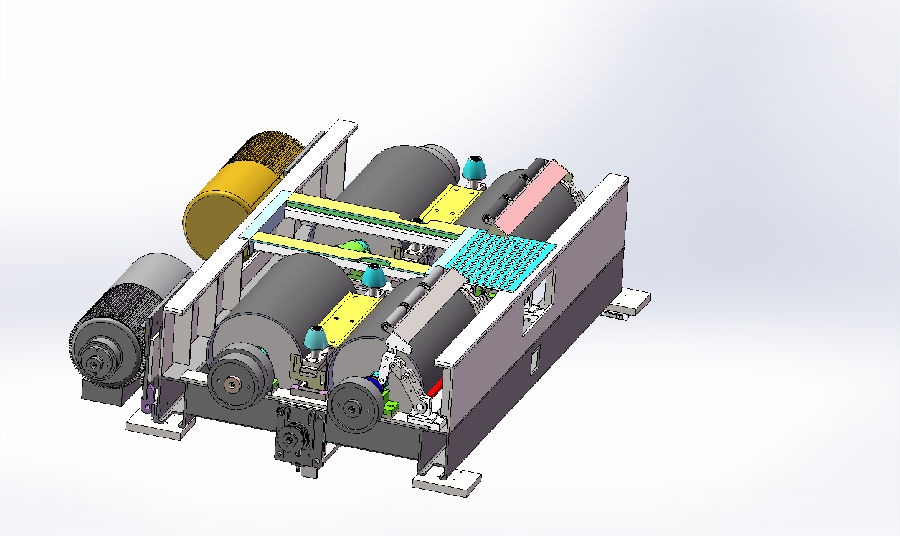

- Introduction to the main components of the comprehensive drum test bench (2)

- What are the main components of the drum table?

- What are the main components of the drum table? (2)

- Introduction to technical parameters of comprehensive drum test bench

- Scope of supply of comprehensive drum test bench equipment

- Instructions for use of the contact type dynamic surface measurement 4 wheel alignment instrument (I)

- Instructions for use of the contact type dynamic surface measurement 4 wheel alignment instrument (2)

- Basic structure and working principle of contact type dynamic surface measurement 4 wheel alignment instrument (I)

- Basic structure and working principle of contact type dynamic surface measurement 4 wheel alignment instrument (2)

- Contact type dynamic surface measurement 4 wheel alignment instrument test process