1. Basic structure and functional structure characteristics:

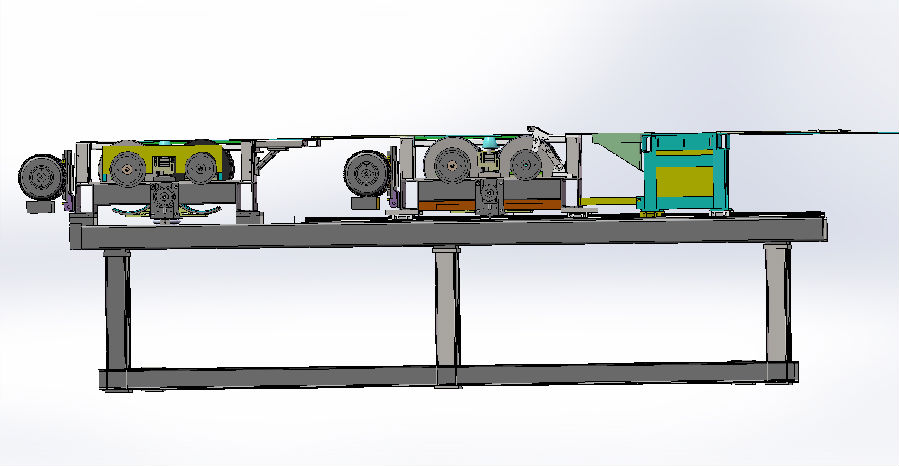

Comprehensive drum test benchIt uses two sets of integrated rollers, one set is fixed and the other set is movable.

The structure is mainly composed of bracket, mobile base, mobile guide rail, basic frame, motor, reduction wheel, hub assembly, pneumatic lifting device, speed sensor, displacement sensor, inverter and other components.

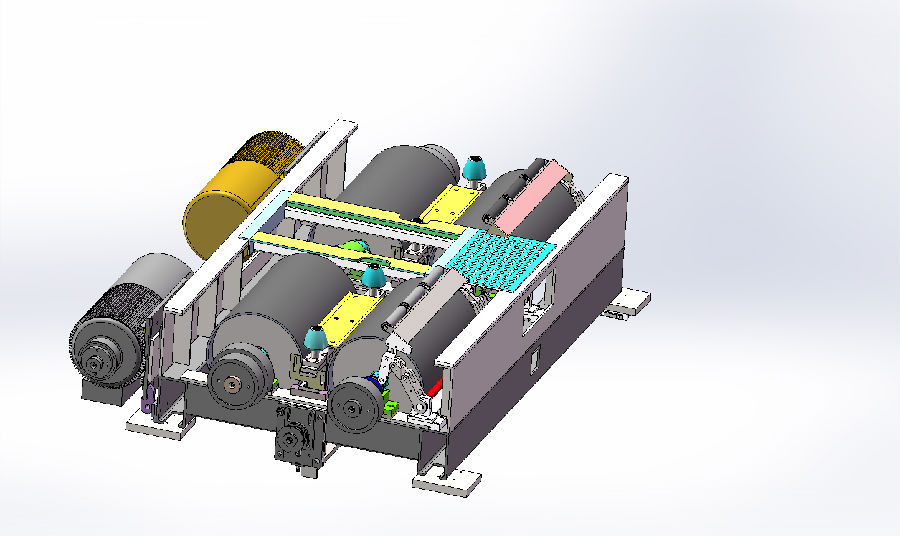

2. Rotary drum body roller group

Each set of rollers consists of two rollers with a diameter of 502 mm and a length of 800 mm. The balance quality of the rollers meets the standards of Q6.3 and ISO 1940. The surface of the rollers is coated, and the coating does not damage the tires. The adhesion coefficient is not less than 0.75 when the rollers are dry and oil-free, and reaches more than 0.65 when there is a small amount of oil and water on the surface of the rollers. The mass inertia of the front and rear axle roller groups can be optimized and determined according to the front and rear axle weight ratios of all models. The test bench has the function of stepless electronic control to simulate the quality of the car, and contains a set of wheelbase adjustment devices: the wheelbase is automatically adjusted according to the model during testing to meet the mixed testing of different models. Any wheelbase can be set according to the model within the wheelbase adjustment range. Wheelbase adjustment speed: 60mm\/s; wheelbase adjustment accuracy: ±1mm.

The equipment includes 2 sets of limit safety rollers to prevent the car from rushing forward or exiting the test bench.

The equipment includes 4 sets of lateral limit wheels: to prevent the car from moving sideways on the test bench and causing damage to the tires and rims.

Equipment includes safety facilities: The test bench should have all necessary safety equipment and safety functions to protect the operator's safety and avoid damage to the vehicle and test bench.

The equipment includes a pneumatic system: the pneumatic system is connected to the user's compressed air network.

The equipment includes 1 set of operator control panel: located on the ground near the left front axle, with adjustable support height.

The equipment includes an exhaust gas collection device: located behind the rear drum assembly, it moves with the wheelbase adjustment device to keep the distance from the rear of the vehicle unchanged. The device communicates with the main controller of the equipment to ensure that it is automatically raised only during the test and lowered underground at other times, and does not interfere with the vehicle when it passes by. The exhaust gas collection device is divided into two parts, left and right, to adapt to vehicles with different exhaust pipe positions.

Related News

- How does the dynamic four wheel aligner avoid communication interference?

- Introduction to vehicle electrical inspection

- How to choose a good pass four wheel aligner

- What is the assembly line

- The important role of the through four wheel aligner

- The four main points of 3D laser four wheel aligner maintenance

- Working principle of electric chassis dynamometer

- Vehicle off-line comprehensive diagnostic equipment

- How to choose a good dynamic four wheel aligner

- Precautions for selecting a non-contact four-wheel aligner

- Comprehensive drum test bench program instructions (2)

- Introduction to the main components of the comprehensive drum test bench (2)

- What are the main components of the drum table?

- What are the main components of the drum table? (2)

- Introduction to technical parameters of comprehensive drum test bench

- Scope of supply of comprehensive drum test bench equipment

- Instructions for use of the contact type dynamic surface measurement 4 wheel alignment instrument (I)

- Instructions for use of the contact type dynamic surface measurement 4 wheel alignment instrument (2)

- Basic structure and working principle of contact type dynamic surface measurement 4 wheel alignment instrument (I)

- Basic structure and working principle of contact type dynamic surface measurement 4 wheel alignment instrument (2)