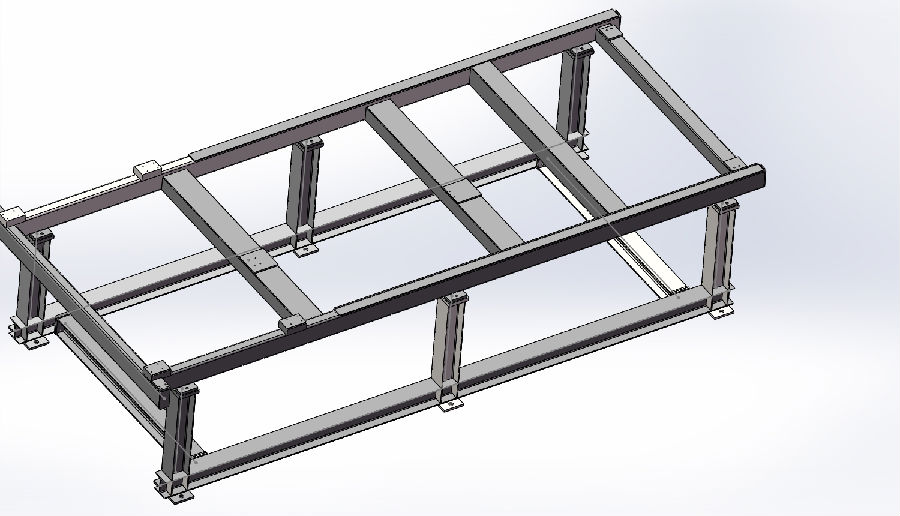

1. Basic Framework

Used to support the roller group, the frame is welded by I-beam steel plate and channel steel, with sufficient strength and rigidity. It is easy to install and debug, and when the frame has a small deformation, it will not cause adverse effects on the rotating parts.

It is made of rectangular tube and steel plate, with good rigidity, centered pressure and no eccentric load. The base is fixed and connected to the foundation through the legs. The whole base has been reliably treated with aging to ensure long-term operation without deformation. The guide rail mounting surface on the base is processed by a large gantry milling machine with one-time clamping and high positioning accuracy.

The legs of the base are evenly distributed under the base, which stably lifts up the entire test bench and leaves a space of one person's height under the test bench, which is convenient for maintenance and adjustment of the test bench.

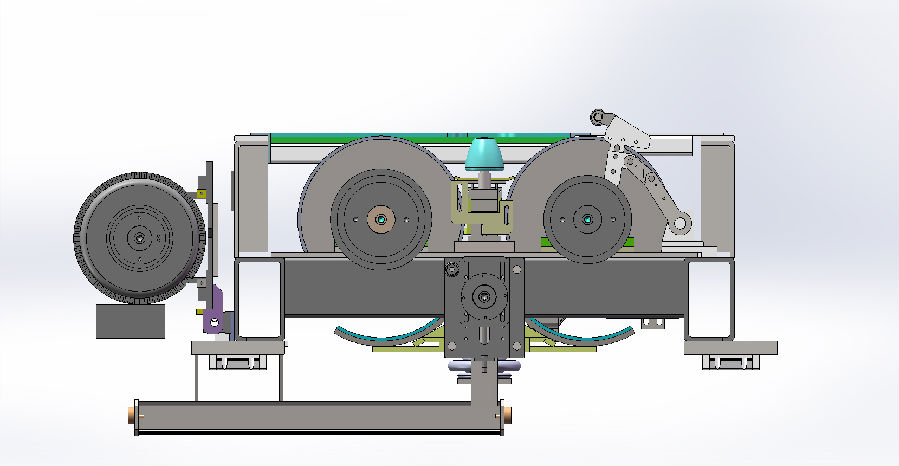

2. Drum parts

There are 4 sets of drum parts, 2 of which are placed in front of the drum platform as fixed parts, used to support the front wheels of the car. The other 2 sets are placed behind the drum platform as mobile parts, used to support the rear wheels of the car. The mobile parts are driven by a wheelbase adjustment mechanism and can adapt to vehicles with different wheelbases.

This part consists of motor, synchronous belt, drum, support bearing, safety gear wheel, etc. The motor is a 37Kw AC motor, driven by a 4-quadrant inverter, and can work in driving and generating states.

Each set of rollers consists of two rollers with a diameter of 502 mm and a length of 800 mm. The balance quality of the rollers meets the standards of Q6.3 and ISO 1940. The surface of the rollers is coated, and the coating does not damage the tires. The adhesion coefficient is not less than 0.75 when the rollers are dry and oil-free, and reaches more than 0.65 when there is a small amount of oil and water on the surface of the rollers. The mass inertia of the front and rear axle roller groups can be optimized and determined according to the front and rear axle weight ratios of all models. The test bench has the function of stepless electronic control to simulate the quality of the car, and contains a set of wheelbase adjustment devices: the wheelbase is automatically adjusted according to the model during testing to meet the mixed testing of different models. Any wheelbase can be set according to the model within the wheelbase adjustment range. Wheelbase adjustment speed: 60mm\/s; wheelbase adjustment accuracy: ±1mm.

The equipment includes 2 sets of limit safety rollers to prevent the car from rushing forward or exiting the test bench.

The equipment includes 4 sets of lateral limit wheels: to prevent the car from moving sideways on the test bench and causing damage to the tires and rims.

Equipment includes safety facilities: The test bench should have all necessary safety equipment and safety functions to protect the operator's safety and avoid damage to the vehicle and test bench.

The equipment includes a pneumatic system: the pneumatic system is connected to the user's compressed air network.

The safety stop wheel consists of a cylinder, a connecting rod and a stop wheel. This device can not only maintain the stability of the vehicle on the drum, but also serve as the third roller to measure the test data.

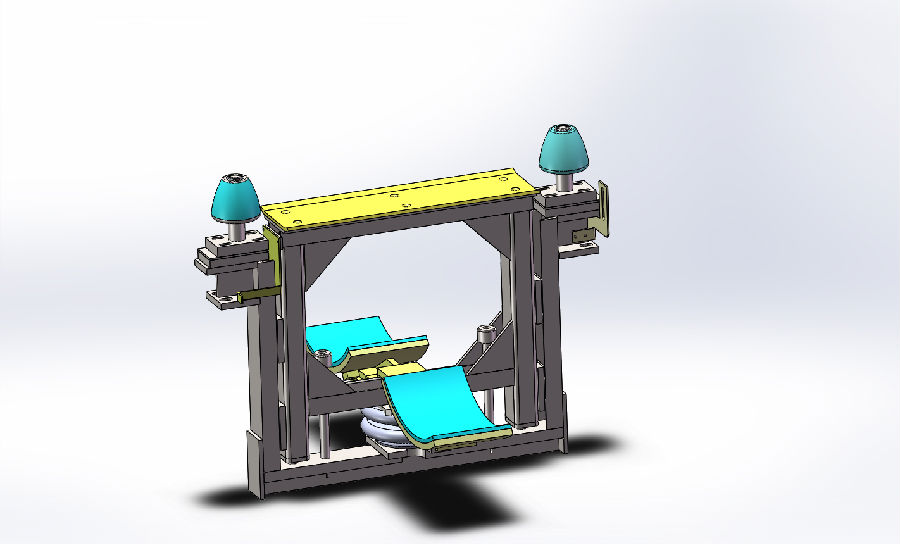

3. Lifter

The lifting and lowering of the lift allows the car to easily enter or leave the roller group.

This component is arranged in the center of each set of drums, for a total of 4 sets.

This component is composed of airbags, linear guides, and lifting frames. Its function is to lift the car to the highest point of the drum to facilitate the car to enter and exit the test bench. The perfect coordination of the linear guides can keep the lifting and lowering of the two sides synchronized.

4.Safety protection roller

Safety rollers prevent the vehicle from running out of or exiting the roller group during testing.

5. Test bench cover (inner and outer cover)

A complete set of cover plates and supporting steel structures are used in the test bench area to maximize the friction with the wheels and facilitate vehicle entry and exit.

6. Wheelbase adjustment mechanism

It consists of servo motor, trapezoidal screw and other accessories. The purpose is to make the drum behind the test bench accurately positioned front and back according to the different wheelbases to adapt to different models. The wheelbase adjustment mechanism can be automatically completed after the equipment scans the code. The adjusted wheelbase can be accurately positioned and reliably locked.

Related News

- How does the dynamic four wheel aligner avoid communication interference?

- Introduction to vehicle electrical inspection

- How to choose a good pass four wheel aligner

- What is the assembly line

- The important role of the through four wheel aligner

- The four main points of 3D laser four wheel aligner maintenance

- Working principle of electric chassis dynamometer

- Vehicle off-line comprehensive diagnostic equipment

- How to choose a good dynamic four wheel aligner

- Precautions for selecting a non-contact four-wheel aligner

- What are the main components of the drum table? (2)

- Introduction to technical parameters of comprehensive drum test bench

- Scope of supply of comprehensive drum test bench equipment

- Instructions for use of the contact type dynamic surface measurement 4 wheel alignment instrument (I)

- Instructions for use of the contact type dynamic surface measurement 4 wheel alignment instrument (2)

- Basic structure and working principle of contact type dynamic surface measurement 4 wheel alignment instrument (I)

- Basic structure and working principle of contact type dynamic surface measurement 4 wheel alignment instrument (2)

- Contact type dynamic surface measurement 4 wheel alignment instrument test process

- Installation and calibration preparation of 4-wheel alignment instrument for contact dynamic surface measurement

- Contact type dynamic surface measurement 4 wheel alignment instrument wheelbase adjustment