The electric chassis dynamometer, also known as the electric drum test bench, is an indoor test equipment. It is used to simulate the resistance of the car when it is actually driving, measure the performance of the car, detect the technical condition of the car, and diagnose car faults. The chassis dynamometer can be used for both scientific testing of automobiles and maintenance production.

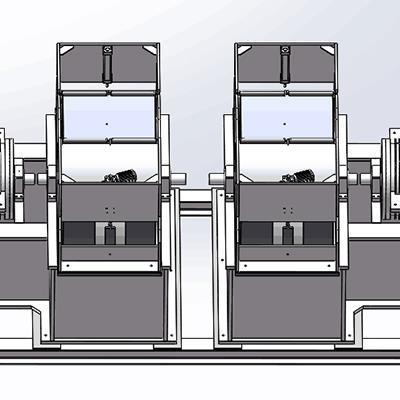

Chassis dynamometers are mostly made of steel plate bending and integrally welded bodies, which have good strength and beautiful appearance. They do not require anchor bolts for installation, and the wiring and air source are connected by connectors, which makes installation and commissioning extremely convenient, especially for temporary lifting in flooded areas when necessary. They are lifted by single-beam air bags, with good lifting synchronization, maintenance-free, and refueling-free. They are mainly used to detect engine power with an unloaded dynamometer, and chassis dynamometers to detect the maximum output power and maximum speed of the car. The maximum chassis driving power of the vehicle is detected by the chassis dynamometer to assess the technical condition level of the vehicle. It is composed of a roller, a power absorption unit, and an inertia simulation device to simulate the road resistance of the vehicle.

The chassis dynamometer is a special measuring device used to measure the output power of the vehicle's drive wheels, the vehicle's acceleration performance, the vehicle's fuel economy and exhaust emission performance, and the driving force and speed. The main parts of the chassis dynamometer are the roller mechanism, power absorption device, control and measurement system and auxiliary devices. Some chassis dynamometers are equipped with flywheel systems, etc., and can also measure the vehicle's acceleration performance and sliding performance.

Related News

- How does the dynamic four wheel aligner avoid communication interference?

- Introduction to vehicle electrical inspection

- How to choose a good pass four wheel aligner

- What is the assembly line

- The important role of the through four wheel aligner

- The four main points of 3D laser four wheel aligner maintenance

- Working principle of electric chassis dynamometer

- Vehicle off-line comprehensive diagnostic equipment

- How to choose a good dynamic four wheel aligner

- Precautions for selecting a non-contact four-wheel aligner

- How to ensure the normal operation of the through-type 4-wheel alignment instrument

- Usage and maintenance of dynamic 4-wheel alignment instrument

- What are the misconceptions car owners have about non-contact 4-wheel alignment

- What is the importance of dynamic 4 wheel alignment nowadays?

- Let's understand the dynamic 4 wheel alignment market

- Comparison of the characteristics and cost analysis of 3D dynamic positioning platform and static 3D positioning instrument

- Comparison between dynamic 4 wheel aligners and static aligners

- What is the difference between a static 4-wheel alignment instrument in a repair shop and a dynamic surface measurement 4-wheel alignment instrument in a car factory?

- Comprehensive Drum Test Bench Program Specification (I)

- Introduction to the main components of the comprehensive drum test bench (I)