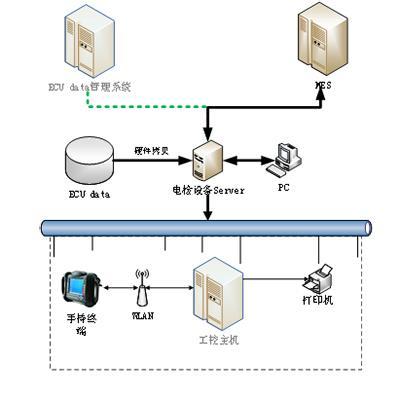

According to the vehicle electrical inspection electrical subsystem, the host power supply, electronic wiring harness, grounding function test and others are pointed out to obtain the deviation of the main parameters of the new model electrical equipment and the design indicators, so as to analyze the impact on the function and performance of household appliances.

Before the vehicle electrical performance test, the vehicle and the test equipment must be checked to ensure normal function. According to the data monitoring type, the corresponding test equipment (Table 3) must be planned. Before the test, a functional test must be performed according to the test data (Table 3). The functional test includes detailed fuse type and limit, fuse protection load and load wiring harness information, specific positioning points for each test, and the main power supply status of the vehicle during the test.

The actual operation is carried out according to the load working host power supply status. The host power supply status when not idling can be divided into OFF, ACC, and ON gears. At this time, in order to simulate the generator voltage output when the vehicle is started, the program-controlled power supply is connected in parallel to the positive and negative terminals of the battery, and the output voltage is set to 14.50±0.2V. According to the detection matrix, each positioning point is tested one by one and the data and phenomena are analyzed in detail according to the evaluation criteria. Combined with the data recorded during the test, the causes of the deviation items (test items that do not meet the design requirements) are analyzed. Write a test report.

Taking the load dump test as an example, the test results of the vehicle electrical inspection are as follows.

Mondeo load dump test: Battery SOC 70%, vehicle speed 2000r\/min test, disconnect the battery positive terminal for a moment, low beam, high beam all filaments burn out.

According to the test conclusion, the generator of the test vehicle is equipped with a voltage regulator suppression circuit, and the specific measurement Us=25.2V; the enterprise standard stipulates that the pulse Us value is less than or equal to 21.5V; the evaluation conclusion exceeds the standard seriously.

The low beam and high beam bulbs of this test vehicle are all Osram H7U models, with specific main parameters of 12V, 55W.

Channel 1 is the battery voltage, channel 2 is the bulb voltage, and channel 3 is the bulb current. The bulb's transient high current reaches 10.9A>4.58A (rated current), the voltage is 25.2V>12V (rated voltage), and the instantaneous power reaches 274.68W>55W (rated power), causing the bulb to burn out.

Corrective suggestions: ①Reselect the generator to ensure that the specific suppression voltage Us is less than or equal to 21.5V; ②Improve the function of the light bulb to ensure that it can withstand a momentary large voltage pulse.

The design ideas of the electrical equipment subsystem and the test methods of the vehicle electrical inspection function are briefly analyzed. Taking load dump as an example, the test results are analyzed and rectification measures are given.

Related Industry Knowledge

- ADAS advanced auxiliary driving calibration equipment calibration purpose

- What is the function of the high-speed ABS brake test rig?

- Introduction to non-contact four-wheel aligner

- Main configuration of ABS brake table

- Safety inspection project

- Comprehensive drum test bench product introduction

- Tire pressure equipment operating instructions

- Non-contact four wheel aligner operating procedures

- Application of laser measurement technology in automobile four wheel aligner

- Dynamic four wheel aligners have formed a trend

- Explanation of the detection methods of vehicle electrical inspection

- ABS brake function characteristics

- What value can the use of 4 wheel alignment instruments bring to everyone?

- 3D Laser 4 Wheel Alignment Test Principle

- Ideal operating frequency of 3D laser 4 wheel alignment

- How often should I do a dynamic 4-wheel alignment inspection?

- Why can the dynamic 4-wheel alignment be recognized by many car owners?

- Dynamic 4-wheel alignment detection method

- Why is the dynamic 4-wheel alignment so popular among many car enthusiasts?

- Dynamic 4 wheel alignment function and technical standards