Manual Operation

The manual operation of 4-wheel alignment is to manually test the operating parts of the equipment. The following figure (6-1) is the manual operation interface:

(6-1)

Manual operation includes manual operation of the front and rear wheels. During debugging, we can perform manual operation according to the buttons on the interface. We will not explain them one by one here.

Equipment calibration zeroing

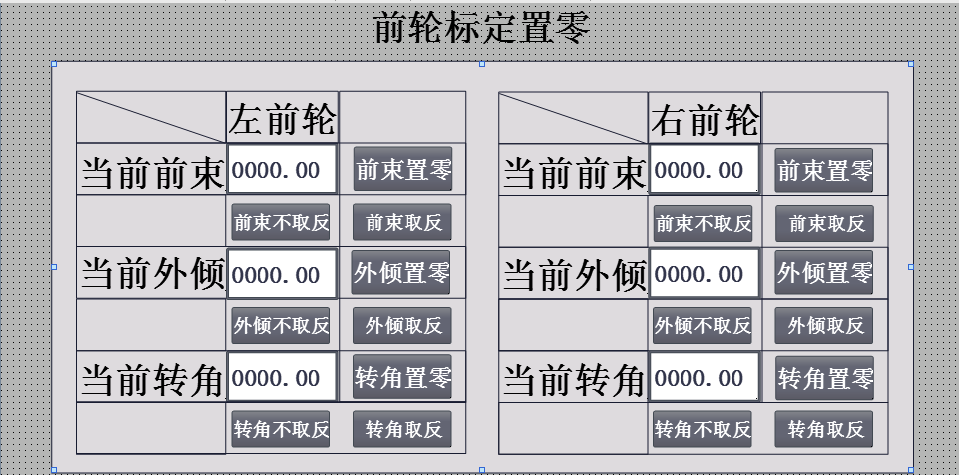

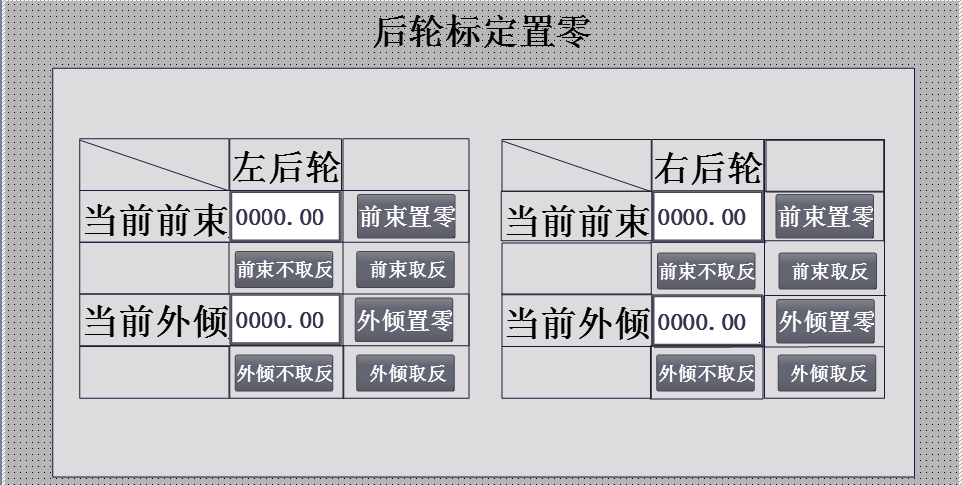

The 4-wheel alignment equipment is calibrated and zeroed based on the calibration disk provided by our company. The following figure (7-1) is the touch screen interface for the front wheel calibration and zeroing, and figure (7-2) is the touch screen interface for the rear wheel calibration and zeroing:

(Figure 7-1)

(Figure 7-2)

Front wheel calibration

After opening the front wheel calibration zeroing interface, push the calibration disk onto the front wheel detection disk, open the manual interface, and use the manual button to lower the lift and extend the detection head. The motor rotates 23 times before stopping, and returns to the calibration interface to reset each value to zero. The invert and non-invert buttons on the interface are used to process the positive and negative data. The default is non-invert, so it is generally not necessary to invert here.

Rear wheel calibration

Open the rear wheel calibration zeroing interface. The following steps are the same as the front wheel calibration method and are omitted here.

Related News

- How does the dynamic four wheel aligner avoid communication interference?

- Introduction to vehicle electrical inspection

- How to choose a good pass four wheel aligner

- What is the assembly line

- The important role of the through four wheel aligner

- The four main points of 3D laser four wheel aligner maintenance

- Working principle of electric chassis dynamometer

- Vehicle off-line comprehensive diagnostic equipment

- How to choose a good dynamic four wheel aligner

- Precautions for selecting a non-contact four-wheel aligner

- Contact type dynamic surface measurement 4 wheel alignment instrument toe-in, camber, caster detection

- 4. Detection of the maximum turning angle of the wheel aligner

- 4. Kingpin inclination detection of wheel alignment instrument

- Introduction to the inspection method of 3D laser 4-wheel alignment

- Will the installation of a 4-wheel alignment have any impact on the car?

- What are the technical standards for 3D4 wheel alignment

- Maintenance during the use of 3D laser 4 wheel alignment

- Dynamic 4 wheel alignment manufacturer talks about several angles of 4 wheel alignment

- Analysis of the Function and Operation Process of Automobile 4-Wheel Alignment Instrument

- Things to note when purchasing a dynamic 4 wheel alignment instrument