Since the non-contact 4-wheel alignment instrument appeared on the market, it has swept the country within 2 to 3 years. The product has been recognized by users for its high measurement efficiency and low failure rate. The advantages of high-tech elements are recognized by users. The 4-wheel measurement efficiency is high and the failure rate is low. The new generation of products is more efficient, more convenient and more accurate. We have to admire that the development and progress of science and technology is so fast.

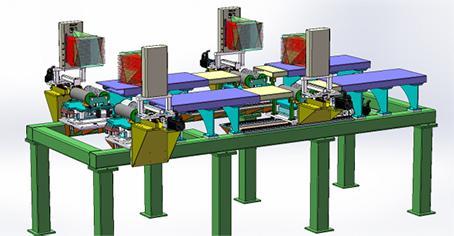

The non-contact 4-wheel alignment instrument consists of a 4-column hoist, 4 measurement units for front, rear, left and right, and a computer console. The 4-wheel alignment instrument abandons the wheel clamps of the traditional 4-wheel alignment instrument and can measure the 4-wheel alignment data without contacting the car tires or steel rings.

The 4-wheel aligner does not need to remove the wheel clamp and target like the traditional 4-wheel aligner, avoiding damage to the rim during the measurement process. At the same time, this technology does not require compensation for the trolley. These advantages can reduce the work intensity of automobile repair companies and greatly improve measurement efficiency.

Even so, the important performance of the 4-wheel aligner is the measurement accuracy. This non-contact 4-wheel aligner consists of 4 measurement units, including high-quality industrial cameras, safe infrared lasers and advanced coordinate systems. At the same time, in order to adapt to the changes in the wheelbase of the measured vehicle, the measurement unit is installed on a chute and can move forward and backward.

We have reason to believe that 4-wheel aligners will replace traditional laser aligners, 3D 4-wheel aligners will become inevitable, and China's non-contact 4-wheel aligners will also go global.

Related News

- How does the dynamic four wheel aligner avoid communication interference?

- Introduction to vehicle electrical inspection

- How to choose a good pass four wheel aligner

- What is the assembly line

- The important role of the through four wheel aligner

- The four main points of 3D laser four wheel aligner maintenance

- Working principle of electric chassis dynamometer

- Vehicle off-line comprehensive diagnostic equipment

- How to choose a good dynamic four wheel aligner

- Precautions for selecting a non-contact four-wheel aligner

- The manufacturer of through-type 4-wheel alignment instrument shares the main detection methods of 4-wheel alignment instrument

- What is the relationship between the through-type 4-wheel alignment and the deviation of the car?

- Under what circumstances is it necessary to use a dynamic 4-wheel alignment instrument for 4-wheel alignment?

- What are the functions of dynamic 4 wheel alignment

- 4. Detection of the maximum turning angle of the wheel aligner

- 4. Kingpin inclination detection of wheel alignment instrument

- Introduction to the selection of dynamic 4 wheel alignment

- What are the benefits of dynamic 4 wheel alignment?

- 安规检测不合格?常见电气安全问题(耐压、接地、绝缘)分析与整改