Vehicle performance tester

System plan introduction

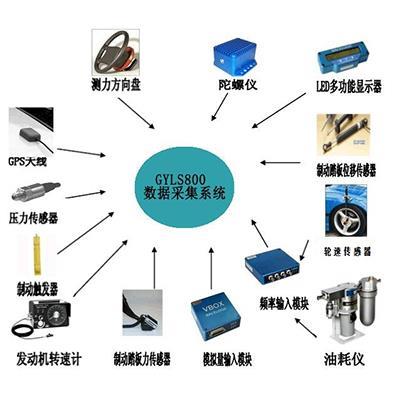

GYLS800 motor vehicle comprehensive performance test system is the latest intelligent test system developed by our company. The whole vehicle off-line comprehensive diagnostic equipment is based on notebook computer, with data collector and various sensors (GPS, photoelectric or five-wheel speed sensor). , fuel consumption sensor, three-axis seat cushion sensor, gyroscope, wheel speed sensor, steering angle measuring instrument, etc.), used in motor vehicles (including electric / hybrid vehicles) power, economy, ride, steering stability , anti-lock system (ABS) performance test and results analysis, and has the functions of data storage, data processing, printing test results and curves.

The system is flexible in operation, convenient to carry, accurate in measurement, stable in operation, and intuitive in reading, which can greatly improve the test accuracy and efficiency. It is an ideal test system for the research and production departments of motor vehicles and the automotive industry of colleges and universities.

System Configuration

(1) A set of data acquisition system (host with supporting software, magnetic antenna, brake trigger, battery pack, charger, multi-function display)

(2) Frequency input module

(3) Analog input module

(4) Charge amplifier

(5) Gyroscope

(6) Force steering wheel

(7) Brake pedal force sensor

(8) Brake pedal force displacement sensor

(9) Brake line pressure sensor

(10) Wheel sensor

(11) Laptop

(12) printer

Characteristics

1. Comprehensive, a system can realize the functions that need to be completed by multiple sets of instruments in the past, so as to avoid users repeatedly adding equipment;

2. All test items share sensors to prevent users from repeatedly adding sensors. 3. Multiple sensors can work at the same time, and the system automatically collects in real time;

4. Under the premise of ensuring the test frequency response, try to replace the hardware function with software, so that the hardware circuit is simple and reliable, easy to maintain, and reduce the procurement cost of user equipment;

5, the data collector sampling frequency can be as high as 256Hz, fully meet the test requirements of high real-time requirements such as braking and ride comfort;

6, can be equipped with a variety of different types of sensors, especially GPS speed sensors, easy to operate;

7. Synchronous real-time test of vehicle speed and wheel speed to achieve quantitative test of wheel slip ratio (anti-lock system (ABS) performance test);

8, the system software is based on the windows platform, graphic interface, easy to use;

9, powerful data processing functions, automatically generate a variety of national standard forms (word or excel format) and curves (bmp format), greatly reducing the user's work intensity.

10. Users can choose to purchase each test sub-system (such as power, economy, ride comfort, steering stability, anti-lock system (ABS) performance test, etc.) and select various brands and precision sensors.